Swift Tahoe Instrument Cluster Repair: Fixing Gauge Malfunctions Today

Swift Tahoe Instrument Cluster Repair: Fixing Gauge Malfunctions Today

Blog Article

Ultimate Resource for Advanced Automobile Tool Cluster Repair Methods

In the world of contemporary vehicle maintenance, the intricacies of instrument collection repair stand as an essential aspect of ensuring the ideal functioning of a car. By discovering the devices required, typical issues experienced, and step-by-step repair work techniques, one can furnish themselves with the knowledge required to navigate the intricate globe of vehicle instrument collection repair work with confidence and precision.

Importance of Advanced Tool Cluster Repair

Recognizing the importance of sophisticated instrument collection repair work is vital for preserving the capability and precision of modern lorry systems. The instrument cluster acts as the center of info for vehicle drivers, showing crucial information such as speed, gas levels, engine temperature, and advising indications. With the advancement of innovation, tool clusters have advanced to incorporate complicated digital components and electronic displays, making repair services a lot more elaborate and specialized.

Correct repair work and maintenance of the instrument cluster are critical for guaranteeing the security and performance of the automobile. Concerns with the tool cluster can lead to inaccurate analyses, malfunctions in essential systems, and safety risks on the roadway. Advanced tool collection repair techniques involve diagnosing electronic faults, recalibrating sensors, and reprogramming software to bring back ideal performance.

Tools and Tools Needed

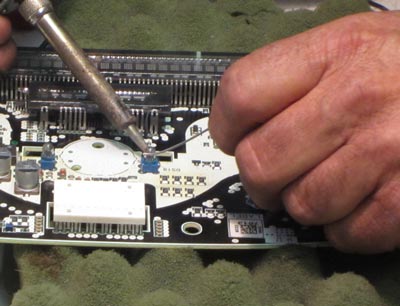

To efficiently deal with the complex repair service needs of modern-day lorry tool collections, a specialized set of devices and tools is important. Some of the secret tools needed for innovative vehicle tool collection repair service include precision screwdrivers, trim elimination devices, soldering devices, electronic multimeters, and diagnostic scanners. Precision screwdrivers are vital for dismantling the collection without creating damages. Trim removal tools help in securely spying off bezels and panels. Soldering equipment is essential for fixing broken links or changing elements. Digital multimeters are used to gauge voltage, continuity, and resistance during analysis procedures. Diagnostic scanners are essential for identifying and repairing electronic issues within the instrument cluster. In addition, having a top quality welding torch, desoldering pump, and solder cable is very important for performing detailed soldering work. Appropriate lights, a magnifying glass, and a tidy office are also vital for guaranteeing accuracy and accuracy during repairs. By having actually these specialized tools and devices accessible, professionals can successfully detect and solve intricate problems in vehicle instrument collections.

Common Issues and Solutions

Numerous typical issues often run into in car instrument collections can be successfully settled via targeted solutions. One common trouble is faulty evaluates, which may result from a malfunctioning stepper motor. To address this, changing the stepper electric motor can bring back precise gauge analyses. One more typical problem is flickering or dark lights on the instrument collection (tahoe instrument cluster repair). This can frequently be credited to more a defective light bulb or bad connections. By changing the light bulb or making sure safe and secure links, the illumination problem can be quickly corrected. Furthermore, a malfunctioning odometer or display screen is a regular problem. This might be because of a malfunctioning display device that requires to be replaced to recover appropriate performance. Finally, intermittent power or complete failure of the tool collection may stem from a blown fuse or wiring concern. Monitoring and changing the fuse, as well as examining the electrical wiring for any problems, can aid settle these power-related problems properly. By determining these common concerns and using the suitable solutions, vehicle instrument cluster capability can be brought back successfully.

Step-by-Step Repair Work Overview

An organized technique to repairing and diagnosing auto instrument collection concerns is vital for attaining exact and effective results. To begin the fixing process, the very first action is to carefully check the instrument cluster for any type of visible damage such as burnt-out light bulbs, fractured screens, or loose links. Next, it is vital to perform an analysis check utilizing customized equipment to identify any underlying electronic problems. When the trouble locations are determined, the repair service can start by either changing damaged parts, repairing damaged circuitry, or recalibrating sensors.

Tips for Preventive Upkeep

After carrying out a comprehensive analysis scan and finishing essential repair services on the automobile tool cluster, applying regular preventative upkeep actions is important to guarantee long-term capability and optimal efficiency of the lorry's necessary assesses and indicators. To begin, it is important to frequently inspect the tool cluster for any kind of indicators of wear, such as fading screens or malfunctioning lights.

Furthermore, upgrading the software application of the tool collection when required can make certain compatibility with any type of new attributes or systems in the automobile. It is likewise advisable to adhere to the producer's recommended upkeep schedule and standards for the tool collection to preserve its longevity. By integrating these preventative upkeep suggestions right into your regular vehicle official statement care, you can aid extend the life expectancy and dependability of your vehicle instrument collection.

Verdict

Finally, advanced automobile tool cluster repair service techniques are essential for preserving the capability of modern cars. By making use of the proper tools and tools, addressing usual issues, and complying with a detailed repair work overview, specialists can successfully fix and identify tool collection troubles. Executing preventative maintenance strategies can help extend the life expectancy of the tool collection and prevent future issues from occurring.

By checking out the devices needed, usual troubles encountered, and step-by-step repair methodologies, one can furnish themselves with the understanding needed to navigate the elaborate globe of auto instrument cluster repair with confidence and accuracy.

A methodical approach to identifying and repairing auto instrument collection concerns is crucial for accomplishing accurate and efficient outcomes. By following this detailed guide carefully, car service technicians can successfully detect and repair instrument collection problems with precision and self-confidence.

In final thought, sophisticated automobile tool cluster repair work strategies are essential for keeping the functionality of modern automobiles. By using the proper devices and devices, attending to typical issues, and adhering to a detailed repair work overview, professionals can successfully identify and repair tool collection problems.

Report this page